Cost-Saving Technologies for Manufacturing Under COVID-19

Manufacturing characteristics include factors such as long lead times, specialized machinery, skilled workforce and operators, maintenance requirements, production defects, and differences between as-sold and as-maintained product configurations. However, a survey conducted by National Association of Manufacturers (NAM) revealed that the majority of those in the manufacturing sector (53%) expect COVID-19 to impact their operations.

During this time of uncertainty and economic slowdown, safeguarding consumer and workforce health is of utmost importance among businesses and governments. Plant closures (full or partial) could continue to be necessary for manufacturers in certain regions for a prolonged period of time. For companies of this nature, this is a critical time to explore a proactive deployment of automation technologies (e.g., robotics, augmented reality & virtual reality, industrial IoT, 3D printing) to decrease worker density throughout their processes as well as cut down their operational costs.

Increased competition between established firms and new tech savvier entrants, together with the ever-mounting pressure to reduce costs, means that it is no longer a matter of hard work alone, but rather a matter of working smarter. The chart below compares the characteristics and benefits of labor arbitrage and labor automation.

Augmented Reality and Virtual Reality

Augmented reality & virtual reality (AR & VR) technologies can be used to virtualize the workplace, improving both the safety and productivity of workers at manufacturing facilities. By using AR & VR, companies can train new hires in a virtual environment without having the risk and cost of putting new employees into the production environment. With AR & VR technologies, companies can also improve employees’ productivity by showing them product information in the virtual space in real-time, helping them find products quickly, and enabling them to collaborate remotely. AR & VR technologies are now mature enough with companies focusing on hardware and software and other companies focusing on content creation. Therefore, manufacturing companies can get a quick win by implementing AR & VR technologies.

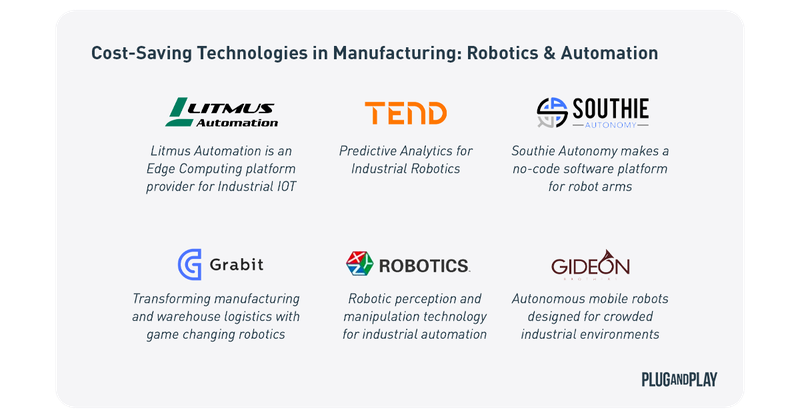

Robotics and Automation

Industries with mass production models can consider robotics to increase output and reduce process variability, thereby improving product quality. Manufacturing robots are generally able to automate repetitive tasks, reduce margins of error, and enable human workers to focus on more productive areas of the operation. Manufacturers do not need to fully upgrade their infrastructure to leverage robotics, as many startups can help companies retrofit their existing machines by adding sensors and adding new software. Manufacturers can also start trying the technology from small robotics such as material handling robots.

3D Printing and Rapid Prototyping

3D printing can cut both costs and time of manufacturing processes and prototyping. Volkswagen estimated it saved them $377,000 by 3D printing fixtures and tools at its Portugal plant in 2017. The process of multiple weeks to get a part and that cost $200 to get the part was reduced to a couple of hours and $20 costs by leveraging additive manufacturing.

Accident Prevention and Operations Monitoring

With the development of computer vision technologies, the industry has found many great use cases in the manufacturing space such as safety and security monitoring, productivity monitoring, quality assurance, or simply object counting. Many of these jobs are still being done manually today, and implementing the computer-vision-based systems can save manufacturers a great amount of money by reducing downtime, reducing required labor, and reducing deficit components or products.

Predictive Maintenance

Machine downtime costs manufacturers a lot for the overall impact it brings to the entire system from the production line to the supply chain. To avoid machine downtime, it is good to be proactive by implementing predictive maintenance techniques. By leveraging machine learning-based computer vision and acoustics techniques, startups can help manufacturers collect data from machines, analyze the abnormalities, and identify the potential problems before they really happen. These predictive maintenance technologies can be applied to a wide range of industrial assets across robotics, machines, pipelines, and vehicles.

Legacy System Modernization

Many companies are still relying on legacy IT systems and not utilizing the rich data that their machines and facilities generate every day. This is a great space where manufacturers can save a great amount of money by picking up new technologies from APIs to AI and machine learning. Startups also realize that there is a gap between the availability of the technologies and the capabilities to leverage those technologies. Therefore, many startups provide simplified tools and platforms to enable manufacturers to build internal API tools, AI and machine learning models, and other monitoring tools without having a big developer team.

Robotic Process Automation

Robotic Process Automation (RPA) deals with simpler types of tasks. It mainly takes away physical tasks that don’t need knowledge, understanding, or insight; the tasks can be done by codifying rules and instructing the computer or software to act. RPA and cognitive automation strategies can drive cost reduction and operational improvement in areas such as procurement process, formulation, invoicing, and pricing.